Materials Science and Manufacturing Engineering Miscellaneous

- Match the Machine Tools (Group A) with the probable Operations (Group B) :

Group A Group B P. Centre Lathe 1. Slotting Q. Milling 2. Counter-boring R. Grinding 3. Knurling S. Drilling 4. Dressing

-

View Hint View Answer Discuss in Forum

Centre lathe - knurling Milling – Slotting Grinding – Dressing Drilling – Center Boring

Correct Option: C

Centre lathe - knurling Milling – Slotting Grinding – Dressing Drilling – Center Boring

- The main cutting force acting on a tool during the turning (orthogonal cutting) operation of a metal is 400 N. The turning was performed using 2 mm depth of cut and 0.1 mm/rev feed rate. The specific cutting pressure (in N/mm2) is

-

View Hint View Answer Discuss in Forum

∴ Specific cutting pressure = Fc = 400 = 2000 N / mm2 W.t 2 × 0.1 Correct Option: B

∴ Specific cutting pressure = Fc = 400 = 2000 N / mm2 W.t 2 × 0.1

Direction: In Orthogonal turning of a bar of 100 mm diameter with a feed of 0.25 mm/rev, depth of cut of 4 mm and cutting velocity of 90m/min. it is observed that the main (tangential) cutting force is perpendicular to the friction force acting at the chip-tool interface. The main(tangential) cutting force is 1500 N.

- The normal force acting the chip-tool interface in N is

-

View Hint View Answer Discuss in Forum

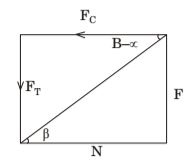

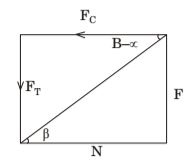

N = Fc .cosα – FT .sinα

∴ α = 0

N = Fc = 1500 NCorrect Option: B

N = Fc .cosα – FT .sinα

∴ α = 0

N = Fc = 1500 N

- The orthogonal rake angle of the cutting tool in degree is

-

View Hint View Answer Discuss in Forum

D = 100 mm feed, f = 0.25 mm/rev d = 4 mm, V = 90m/min, Fc = 1500 N

α = 0

Correct Option: A

D = 100 mm feed, f = 0.25 mm/rev d = 4 mm, V = 90m/min, Fc = 1500 N

α = 0

- Minimum shear-strain in orthogonal turning with a cutting tool of zero rake angle is

-

View Hint View Answer Discuss in Forum

Shear strain , τ = cosα sinφ.cos( φ - α )

where, α = 0 = rake angle , φ = shear angle∴ τ = 1 sinθcosθ

∴ T = sinφcosφdt = cos ²φ - sin ²φ dφ

or φ = 45°∴ τmin = 1 { sin (π /4).cos(π /4) } ∴ τmin = 1 = 2 { sin (1 /√2) × (1 /√2) } Correct Option: D

Shear strain , τ = cosα sinφ.cos( φ - α )

where, α = 0 = rake angle , φ = shear angle∴ τ = 1 sinθcosθ

∴ T = sinφcosφdt = cos ²φ - sin ²φ dφ

or φ = 45°∴ τmin = 1 { sin (π /4).cos(π /4) } ∴ τmin = 1 = 2 { sin (1 /√2) × (1 /√2) }