Materials Science and Manufacturing Engineering Miscellaneous

- A single point cutting tool with 0° rake angle is used in an orthogonal machining process. At a cutting speed of 180 m/min, the thrust force is 490 N. If the coefficient of friction between the tool and the chip is 0.7, then the power consumption (in kW) for the machining operation is_____.

-

View Hint View Answer Discuss in Forum

α = 0

so

F = FT

N = FcF = FT N Fc 490 = 0.7 Fc

Fc = 700 NPower = Fc × V = 700 × 180 = 2.1kw 60 Correct Option: A

α = 0

so

F = FT

N = FcF = FT N Fc 490 = 0.7 Fc

Fc = 700 NPower = Fc × V = 700 × 180 = 2.1kw 60

- An orthogonal turning operation is carried out under the following conditions; rake angle = 5°, spindle rotational speed = 400 rpm; axial feed = 0.4 m/min and radial depth of cut = 5 mm. The chip thickness tc, is found to be 3 mm. The shear angle (in degree) in this turning process is______.

-

View Hint View Answer Discuss in Forum

µ= 5° N = 400 rpm f = 0.4m/min

f = 0.4 × 1000 = 1 mm/res = t1 400

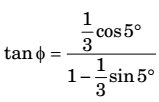

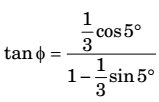

t2 = 3 mmtanΦ = r cos ∝ 1 - tsin ∝

r = t1 = 1 t2 3

tanΦ = 0.342

Φ = 18.88Correct Option: C

µ= 5° N = 400 rpm f = 0.4m/min

f = 0.4 × 1000 = 1 mm/res = t1 400

t2 = 3 mmtanΦ = r cos ∝ 1 - tsin ∝

r = t1 = 1 t2 3

tanΦ = 0.342

Φ = 18.88

- Under certain cutting conditions, doubling the cutting speed reduces the tool life to (1/16)th of the original. Taylor's tool life index(n) for this tool- work piece combination will be ________.

-

View Hint View Answer Discuss in Forum

VTn = C

V1 T1n = 2V1 ×

T1

2 on solving we get 16

n = 0.25Correct Option: A

VTn = C

V1 T1n = 2V1 ×

T1

2 on solving we get 16

n = 0.25

- A cast iron block of 200 mm length is being shaped in a shaping machine with a depth of cut of 4 mm, feed of 0.25 mm/stroke and the tool principal cutting edge angle of 30°. Number of cutting strokes per minute is 60. Using specific energy for cutting as 1.49 J/mm3, the average power consumption (in watt) is __________ .

-

View Hint View Answer Discuss in Forum

Specific cutting energy

= Fc = 1.49 J/mm3 b × t1 = Fc 4 × 0.25

Fc = 1.49 J/mm. strokeFc = 1.49 J/mm × 60 min

Fc = 89.4 J/mm.min

Power = Fc .1 = 89.4 × 200 mm J/mm.min

= 17880 J/min

Power = 298 J/S or (W).Correct Option: C

Specific cutting energy

= Fc = 1.49 J/mm3 b × t1 = Fc 4 × 0.25

Fc = 1.49 J/mm. strokeFc = 1.49 J/mm × 60 min

Fc = 89.4 J/mm.min

Power = Fc .1 = 89.4 × 200 mm J/mm.min

= 17880 J/min

Power = 298 J/S or (W).

- Which pair of following statements is correct for orthogonal cutting using a single-point cutting tool?

P. Reduction in friction angle increases cutting force

Q. Reduction in friction angle decreases cutting force

R. Reduction in friction angle increases chip thickness

S. Reduction in friction angle decreases chip thickness

-

View Hint View Answer Discuss in Forum

2Φ + β –α = 90°

as β↓ Φ↑ so less force is required for cutting.Correct Option: D

2Φ + β –α = 90°

as β↓ Φ↑ so less force is required for cutting.