Materials Science and Manufacturing Engineering Miscellaneous

- Match the heat treatment processes (Group A) and their associated effects on properties (Group B) of medium carbon steel

Group A Group B P. Tempering 1. Strengthening and grain refinement Q. Quenching 2. Inducing toughness R. Annealing 3. Hardening S. Normalizing 4. Softening

-

View Hint View Answer Discuss in Forum

Tempering increases Toughness. Quenching affects hardening. Annealing affects softening. Normalizing affects strengthening & Grain Refinement.

Correct Option: B

Tempering increases Toughness. Quenching affects hardening. Annealing affects softening. Normalizing affects strengthening & Grain Refinement.

- The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is

-

View Hint View Answer Discuss in Forum

Correct Option: D

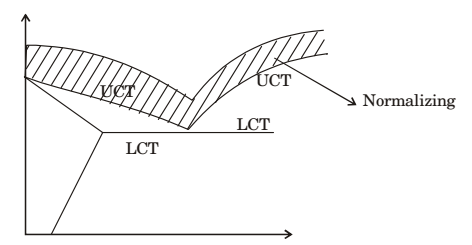

- During normalizing process of steel, the specimen is heated

-

View Hint View Answer Discuss in Forum

LCT-Lower Critical Temperature

UCT-Upper Critical Temperature

Correct Option: C

LCT-Lower Critical Temperature

UCT-Upper Critical Temperature

- Match the items in columns I and II.

Column-I Column-II P. Charpy test 1. Fluidity Q. Knoop test 2. Microhardness R. Spiral test 3. Formability S. Cupping test 4. Toughness 5. Permeability

-

View Hint View Answer Discuss in Forum

Charpy Test - Toughness

Knoop Test - Microhardness

Spiral Test - Fluidity

Cupping Test - FormabilityCorrect Option: D

Charpy Test - Toughness

Knoop Test - Microhardness

Spiral Test - Fluidity

Cupping Test - Formability

- In ECM the MRR is due to

-

View Hint View Answer Discuss in Forum

NA

Correct Option: D

NA