Materials Science and Manufacturing Engineering Miscellaneous

- As tool and work are not in contact in EDM process

-

View Hint View Answer Discuss in Forum

NA

Correct Option: D

NA

- Estimate the MRR (in cc/sec) of an alloy containing 18% cobalt, 62% nickel and 20% chromium during ECM with current of 500 ampere. The density of the alloy is 8.28 g/cc. The following data is available.

Metal Gram atomic weight Valency Cobalt 58.93 2 Nickel 58.71 2 Chromium 51.99 6

Assume Faraday's constant is 96500 coulombs/ mole.

-

View Hint View Answer Discuss in Forum

Given data:

Current (I) = 500 cump.

Density (f) = 8.28 g/cc.MRR = AI ρZF

where, A = atomic weight Z = Valency

F = Faraday’ s constant= 96500

Z

= Z1x1 + Z2x2 + Z3x3 A equivalent A1 A2 A3 = 2 × 0.18 + 2 × 0.62 = 6 × 6 0.2 = 5.03 × 10–2 58.93 58.71 51.99 MRR = 500 8.28 × 5.03 × 10–2 × 96500

= 1.24 × 10–2 CC/sec.Correct Option: B

Given data:

Current (I) = 500 cump.

Density (f) = 8.28 g/cc.MRR = AI ρZF

where, A = atomic weight Z = Valency

F = Faraday’ s constant= 96500

Z

= Z1x1 + Z2x2 + Z3x3 A equivalent A1 A2 A3 = 2 × 0.18 + 2 × 0.62 = 6 × 6 0.2 = 5.03 × 10–2 58.93 58.71 51.99 MRR = 500 8.28 × 5.03 × 10–2 × 96500

= 1.24 × 10–2 CC/sec.

- Machining of complex shapes on CNC machine requires

-

View Hint View Answer Discuss in Forum

NA

Correct Option: A

NA

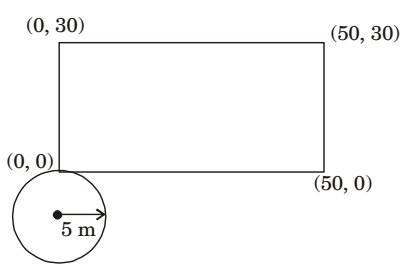

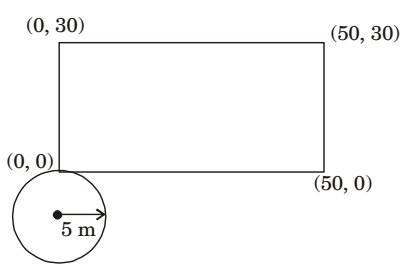

- In finish machining of an island on a casting with CNC milling machine, an end mill with 10 mm diameter is employed, The corner points of the Island are represented by (0, 0), (0, 30), (60, 30) and (50, 0). By applying cutter radius compensation, the trajectory of the cutter will be

-

View Hint View Answer Discuss in Forum

Given = Dia of end milling cutter = 10 mm

Correct Option: B

Given = Dia of end milling cutter = 10 mm

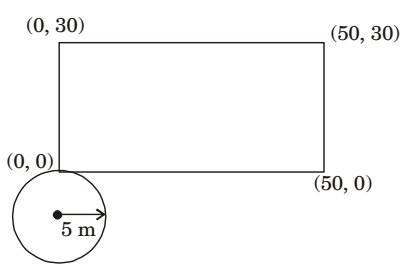

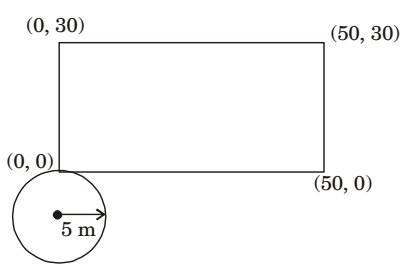

- In finish machining of an island on a casting with CNC milling machine, an end mill with 10 mm diameter is employed, The corner points of the Island are represented by (0, 0), (0, 30), (60, 30) and (50, 0). By applying cutter radius compensation, the trajectory of the cutter will be

-

View Hint View Answer Discuss in Forum

Given = Dia of end milling cutter = 10 mm

Correct Option: B

Given = Dia of end milling cutter = 10 mm