Materials Science and Manufacturing Engineering Miscellaneous

- Match the following products with the suitable manufacturing process

Product Manufacturing Process P. Toothpaste tube 1. Centrifugal casting Q. Metallic pipes 2. Blow moulding R. Plastic bottles 3. Rolling S. Threaded bolts 4. Impact extrusion

-

View Hint View Answer Discuss in Forum

P – 4, Q – 1, R – 2, S – 3

Correct Option: C

P – 4, Q – 1, R – 2, S – 3

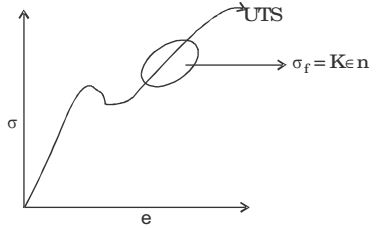

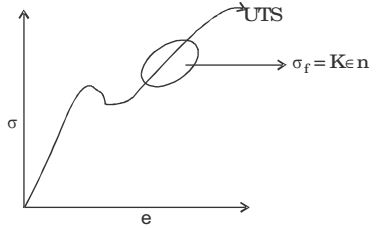

- In a linearly hardening plastic material, the true stress beyond initial yielding

-

View Hint View Answer Discuss in Forum

Correct Option: A

- It is desired to make a product having T-shaped cross-section from a rectangular aluminium block. Which one of the following processes is expected to provide the highest strength of the product?

-

View Hint View Answer Discuss in Forum

Metal forming of Aluminimum is easy because there is negligible strain hardening in Aluminium.

Correct Option: C

Metal forming of Aluminimum is easy because there is negligible strain hardening in Aluminium.

- Engineering strain of a mild steel sample is recorded as 0.100%. The true strain is

-

View Hint View Answer Discuss in Forum

Engg. strain ε = 0.1 100

True strain εT = ln(1 + ε)= In

1 + 0.1

100

= 0.0009995

εT in % = 0.0995%Correct Option: C

Engg. strain ε = 0.1 100

True strain εT = ln(1 + ε)= In

1 + 0.1

100

= 0.0009995

εT in % = 0.0995%

- Match the following products with preferred manufacturing processes:

Product Process P. Rails 1. Blow molding Q. Engine crankshaft 2. Extrusion R. Aluminium channels 3. Forging S. PET water bottles 4. Rolling

-

View Hint View Answer Discuss in Forum

P–4, Q – 3, R –2, S – 1

Correct Option: B

P–4, Q – 3, R –2, S – 1