Industrial Engineering Miscellaneous

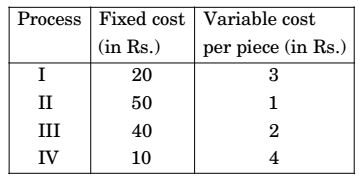

- A component can be produced by any of the four processes I, II, III and IV. The fixed cost and the variable cost for each of the processes are listed below. The most economical process for producing a batch of 100 pieces is

-

View Hint View Answer Discuss in Forum

TC = Fixed Cost + Variable cost

TCI = 20 + 100 × 3 = Rs.320

TCII = 50 + 100 × 1 = Rs.150

TCIII = 40 + 100 × 2 = Rs.240

TCIV = 10 + 100 × 4 = Rs.410

Since total cost for the Process II is minimum

So II is cost for economical point of viewCorrect Option: B

TC = Fixed Cost + Variable cost

TCI = 20 + 100 × 3 = Rs.320

TCII = 50 + 100 × 1 = Rs.150

TCIII = 40 + 100 × 2 = Rs.240

TCIV = 10 + 100 × 4 = Rs.410

Since total cost for the Process II is minimum

So II is cost for economical point of view

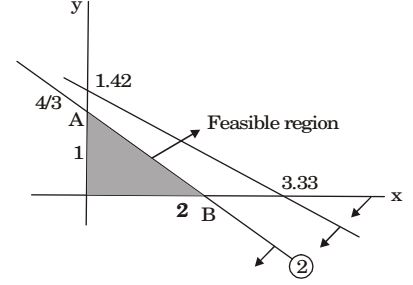

- A linear programming problem is shown below:

Maximise 3x + 7y

Subjeot to 3x + 7y ≤ 10

4x + 6y ≤ 8

x, y ≥ 0

-

View Hint View Answer Discuss in Forum

z = 3x + 7y

Constraints 3x + 7y ≤ 10

4x + 6y < 8; x, y > 0

Corresponding equations

3x + 7y = 10; 4x + 6y = 8

A (0, 4/3) z = 9.23

B (2, 0) z = 6

Thus, exactly one optimal solution.

Hence, the correct option is (b).Correct Option: B

z = 3x + 7y

Constraints 3x + 7y ≤ 10

4x + 6y < 8; x, y > 0

Corresponding equations

3x + 7y = 10; 4x + 6y = 8

A (0, 4/3) z = 9.23

B (2, 0) z = 6

Thus, exactly one optimal solution.

Hence, the correct option is (b).

- A manufacturer can produce 12000 bearings per day. The manufacturer received an order of 8000 bearings per day from a customer. The cost of holding a bearing in stock is Rs. 0.20 per month. Setup cost per production run is Rs. 500. Assuming 300 working days in a year, the frequency of production run should be

-

View Hint View Answer Discuss in Forum

D = 8000 × 300 bearings/year

P = 12000 bearings/day

C = 8000 bearings/day

Ch = 0.12 × 12/year

CO = 500/ProductionQ* = √ 2 × D × CO ×

P

Ch P - C ⇒ √ 2 × 240000 × 500 ×

12000

0.20 × 12 12000 - 8000

⇒ 54772.526T = Q* C

T ⇒ 6.84 daysCorrect Option: C

D = 8000 × 300 bearings/year

P = 12000 bearings/day

C = 8000 bearings/day

Ch = 0.12 × 12/year

CO = 500/ProductionQ* = √ 2 × D × CO ×

P

Ch P - C ⇒ √ 2 × 240000 × 500 ×

12000

0.20 × 12 12000 - 8000

⇒ 54772.526T = Q* C

T ⇒ 6.84 days

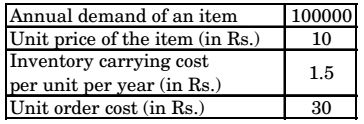

- Consider the following data with reference to elementary deterministic economic order quantity model

The total number of economic orders per year to meet the annual demand is _______.

-

View Hint View Answer Discuss in Forum

D = 100000

C = 10 Rs

Ch = 1.5

CO = 30/orderEOQ(Q*) = √ 2 × D × CO Ch = √ 2 × 100000 × 30 = 2000 units 1.5 No of orders N* = D Q* N* = 100000 ⇒ 50 2000 Correct Option: B

D = 100000

C = 10 Rs

Ch = 1.5

CO = 30/orderEOQ(Q*) = √ 2 × D × CO Ch = √ 2 × 100000 × 30 = 2000 units 1.5 No of orders N* = D Q* N* = 100000 ⇒ 50 2000

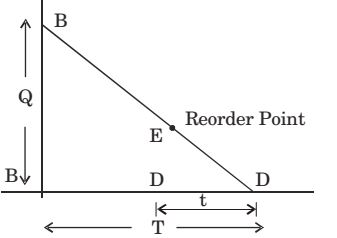

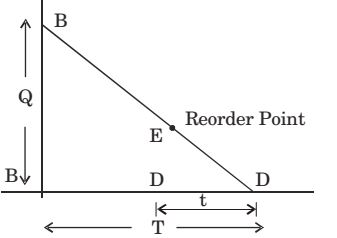

- A company uses 2555 units of an item annually. Delivery lead time is 8 days. The reorder point (in number of units) to achieve optimum inventory is

-

View Hint View Answer Discuss in Forum

Reorder level = LT × d + SS ↑If guessed

Q ⇒ 2555 units

Ls = 8 days

Cycle Time = 365 days

Q = n T t t = Q t T t = 2555 × 8 = 56 units 365 Correct Option: C

Reorder level = LT × d + SS ↑If guessed

Q ⇒ 2555 units

Ls = 8 days

Cycle Time = 365 days

Q = n T t t = Q t T t = 2555 × 8 = 56 units 365